In this post

When working in a business that produces goods it is important to be able to manage stock appropriately. This can be done through the use of many different stock control techniques which have different advantages and disadvantages.

Just-in-time stock control

As we have previously discussed, the just-in-time technique can be used to stop unnecessarily spending money on stock. Instead, this money can be invested into other areas of the business rather than being tied up in stock that is simply sitting in a warehouse.

Imagine the case of a company that makes toiletries. This company has an ongoing production and stockpiles goods in a warehouse where there is approximately £750,000 worth of stock at present. One day, the business has an issue with its machinery and needs to replace this at a cost of £200,000. Since wages and other outgoings have just left the account, the business is a little short on funds. With the £750,000 tied up in stocks, the business does not have the required money to fix the machine and so production slows dramatically and only half the amount of products are produced in the next 2 weeks until the production fault is fixed. In this situation, if the company had not had so much money invested in stock it would have been able to use £750,000 to fix the machinery and ensure that production still ran at the same pace as usual. This would have avoided a lull in production that could have potentially cost the business customers and, ultimately, profit.

Using the just-in-time stock method, a business will have enough money in the bank to invest where things are needed. It will also save money on unnecessary warehouse space as well as avoiding potential loss of money due to stock going out of date or being damaged while in storage.

Just-in-case stock control

An alternative to just-in-time stock control is known as just-in-case. This is a method of stock control that is dramatically different. It involves having a large stock in a warehouse that can be used at any one time if a large order comes in. This type of stock control has very clear disadvantages over just-in-time control as money will be tied up in stock. However, if a business gets an unexpected large order, it will be much quicker to get products to a customer using this approach, as they will be waiting to be dispatched. Another positive of this approach is the fact that it does not leave customers waiting a long time for products to be created and dispatched. A just-in-case approach will mean that orders can be fulfilled much faster.

Bar gate stock graphs

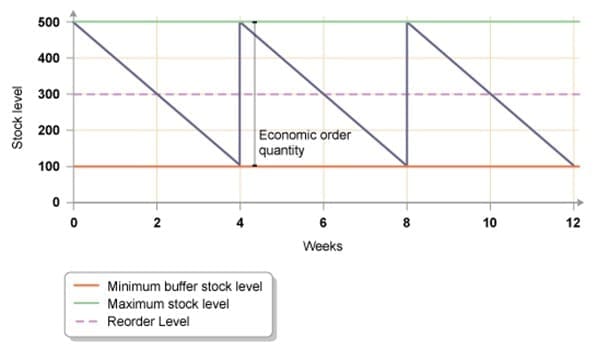

When a just-in-case stock control system is used, a business is likely to use what is known as a gate stock control graph to monitor the amounts of stock in the company. An example of this is shown below:

Using the bar gate stock graph you can monitor the stock level (shown as the blue zigzag line), the minimum stock level, the maximum stock level and the reorder point.

-

- Current stock level – this is the amount of stock that is currently held by the business and will be the thing that is monitored. The stock will go up and down as orders are placed and new items are manufactured. The stock level should always be understood so that the business does not lose any products, manufacture too much and waste resources; or be unable to track the resources that are currently owned by the business.

- Minimum stock level – this is the minimum amount that a business should hold in stock at any one time. The minimum amount will be related to the average size of orders so that the business can fulfil these quickly, the amount of money a business wants to have invested in stock at any one time and the anticipated number of orders to be placed in the near future.

- Maximum stock level – the max stock level will be the most that a business is happy to have in stock. This will be decided by the cost of products (something that is very expensive will not have a high stock level due to the expense of manufacturing), the size of orders that are expected to come through and the length of time it takes to make new products.

- Reorder point – new stock will be reordered in a business when stocks get to a certain point. This reorder point will depend on the time it takes to manufacture new goods and also the minimum level of stock that the business sets in place.